Introduction to Ball Valve- An Isolation Type of Valve

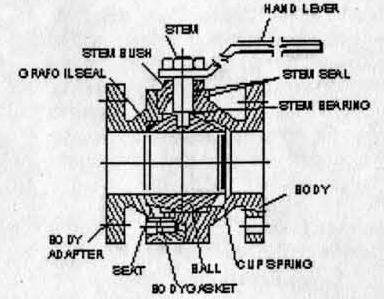

The ball valve is normally used as positive shut off valves. The positive shut off is attained because of the soft seats. Special design is also available with ball having shaped port for regulation. Metal seated ball valves are also available for high temperature service.

They are also considered as quarter turn valves as the closing action is achieved by rotating the lever by 90Deg.They are one of the most widely used valves in process industries because of their versatility, support pressures up to 1000 bar and temperatures up to 482°F (250°C). Sizes typically range from 1/2 to 30 inches. They are easy to repair and operate.

Ball valve |

Ball valve |

The ball valve can be classified based on:

- The type of body construction

- The port size

- The construction of seat

- The construction of ball

The above classification is in addition to the ones based on the end connections, material for construction and the pressure classes. The pressure temperature ratings of the ball valve is generally established by the materials of the seat rings. The service temperatures are also limited by the material of seat rings.

The ball valve offers minimum resistance to the flow. There are two types of designs available as far as the flow area through the valve is concerned. They are the Full Port design and the Regular Port (Reduced Port) design. In full port valves, the port diameter will be equivalent to the nominal size of the valve, whereas in the regular port valves, the port diameter will be one size smaller than the nominal size.