1. Introduction of bimetallic trap

2. Working principle of bimetallic steam trap

3. Improved designed bimetallic trap: Invert disc valve

4. Modified design bimetallic trap: Multiple prongs type

5. Practical limitations in trap operation

6. Advantages of the bimetallic steam trap

7. Disadvantages of the bimetallic steam trap

1. Introduction to Bimetallic Trap:

Bimetallic trap is classified as temperature operated traps (Thermostatic Trap) and it’s by and large the most robust design amongst the various types of traps in common use.

It utilizes bimetallic strips of dissimilar metals stacked together in pairs.

2. Working principle of bimetallic steam trap:

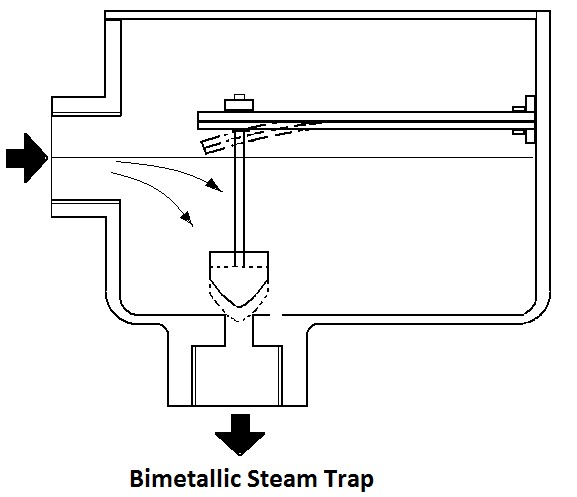

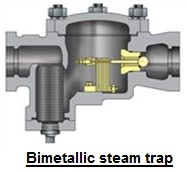

The accompanying sketch (refer Figure-1) below shows the schematic constructional details of the bimetallic trap.

Figure 1: Bimetallic steam trap |

Bimetallic steam trap |

On sensing the temperature of the steam/condensate, owing to dissimilar growth of bimetal, the above strips tend to warp and effectively push the disc down against the seat to stop the flow of fluid through the discharge port.

Similar to Liquid Expansion Trap it is possible in a Bimetallic Trap, to set the discharge temperature of the Condensate by adjusting the position of the lock nut at the top of the deck of the bimetallic strips.

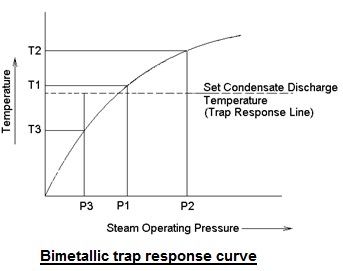

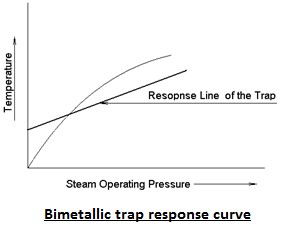

The response line of the trap in the above design is also similar to Liquid Expansion Trap (i.e. as shown in Figure-1) which has its own disadvantages as explained earlier.

Bimetallic trap response curve

3. Improved designed Bimetallic trap: Invert disc valve

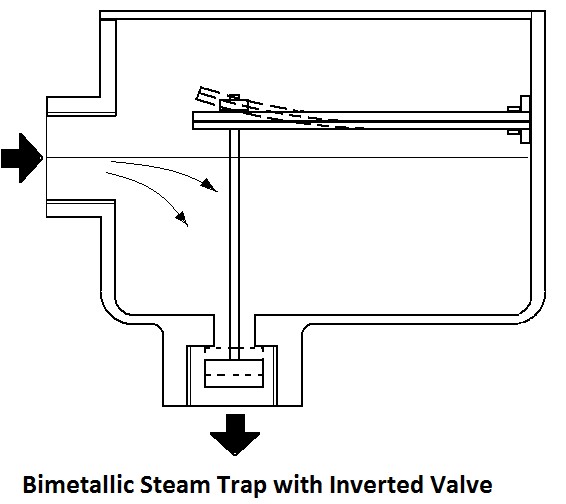

An improved version of the design is possible by utilizing an inverted disc valve and the bimetallic strips arranged in a reverse manner as shown in the sketch (refer Figure-2) below.

Figure-2: Bimetallic steam trap with inverted valve

In such a design the warping of the strips will exert an upward force to pull the disc up against the seat to close the flow passage. The net closure force however being the difference between the axial upward pull (due to warping of strips at temperature) and the downward push due to the line pressure acting on the disc.

As a result the response line of the Trap shows some improvement as shown in the sketch (refer Figure-3) below.

Figure-3: Bimetallic steam trap response curve

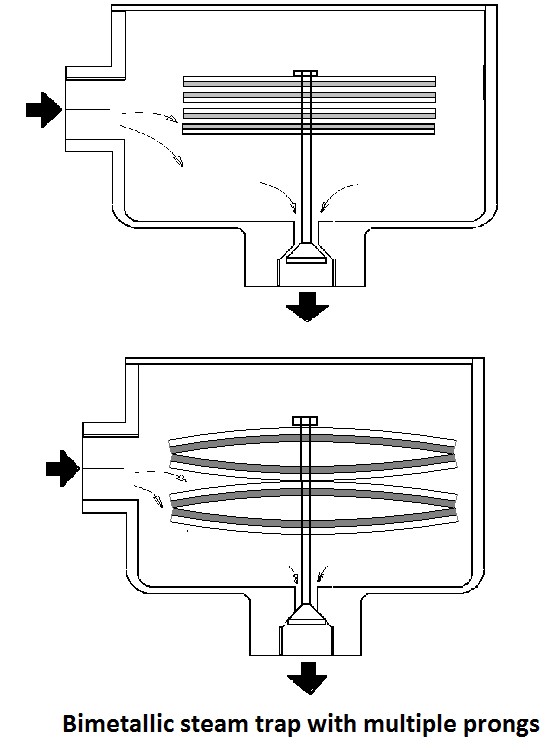

4. Modified design Bimetallic trap: Multiple prongs type

A further improvement in the response line of the above trap is possible by utilizing a modified design of the bimetallic element with multiple prongs as shown in the sketch (refer Figure-4) below.

Figure-4: Bimetallic steam trap with multiple prongs

The clearance and the contour of the above prongs is so manipulated that each pair of it comes into action at different temperature (corresponding to different steam pressure conditions) to result into the required net upward pull of the disc to close the flow passage.

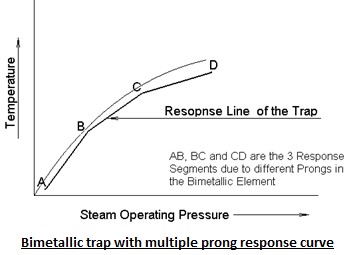

Thereby achieving a response line reasonably close to the steam saturation curve as shown in the sketch (refer Figure-5) below.

Figure-5: Bimetallic steam trap with multiple prongs response curve

5. Practical limitations in trap operation:

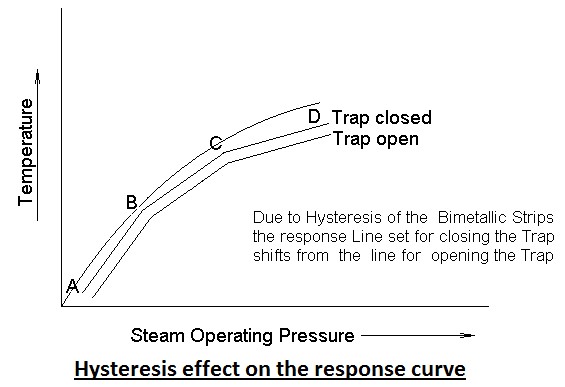

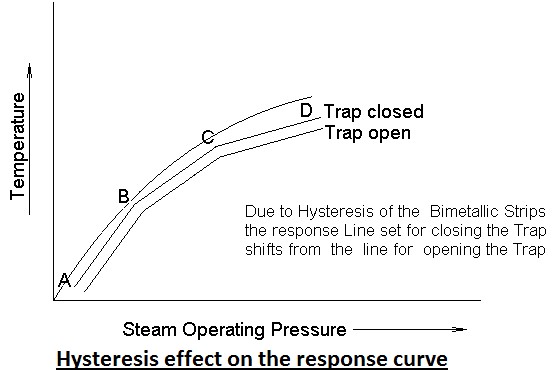

With the above design principle in mind, one may be tempted to believe that it is possible to adjust the settings of the Trap to bring its response line almost approaching to the saturation curve of the steam. However aspects such as Hysteresis of bimetallic strips may pose practical limitations in achieving the same.

Similarly when working with condensate collection systems subject back pressures, a variation in the back pressure may upset the initial settings and it is likely that an increase in the back pressure will cause blowing of live steam through the Trap. The above is demonstrated in the Trap Response Curves in the accompanying sketch (refer Figure-6 and Figure-7) below.

Figure-6: Hysteresis effect on response curve

Figure-7: Hysteresis effect on response curve

It is therefore practical to set the trap response line slightly lower than the steam saturation curve to allow the Condensate discharge with some amount of sub-cooling.

6. Advantages of the bimetallic steam trap:

-

- Fairly robust and compact design

- Fairly high air venting capacity.

- Fairly high resistance to Water Hammer.

- Reasonably good performance against super-heated steam.

- Fairly high thermal efficiency when set to discharge sub-cooled condensate. Possibility of flashing of sub-cooled condensate is minimal.

- Does not require freezing protection under subzero ambient conditions when its discharge is piped as a free draining line.

7. Disadvantages of the bimetallic steam trap:

- Some amount of sub-cooling of condensate cannot be avoided. Modest response to temperature variations.

- Bimetal characteristics may change after being in use for some time. Hence may require servicing.