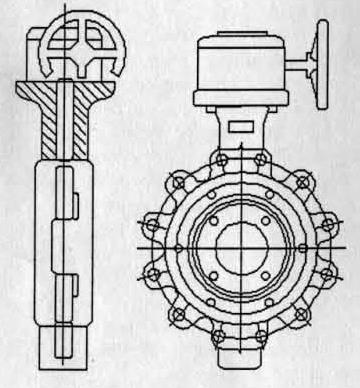

Butterfly valve:

Butterfly valve is one of the types of valves positive shut-off quarter-turn valve. It’s majorly used in utility services such as air, gas, steam, or liquid because of two reasons: they are lower in cost and also they are light in weight. They are available in variety of design depending on the service and the pressure-temperature rating.

These valves can also be used for vacuum service. Whenever used for cryogenic service, the valve shall be provided with extended shaft to clear the insulation.

The major parts of the butterfly valve are:

- Body

- Disc

- Shaft

- Body seat

- Disc seat or seal

- Shaft seal

- Shaft bearing and

- Handle

Butterfly regulation valve

Butterfly regulation valve

Body:

There are three types of body designs possible in a butterfly valve. They are the double flanged type, wafer lug type and wafer type.

In the double flanged body design, the disc is contained within the body and is fitted to the pipe line like any other conventional valve. These types of valves are used rarely as the advantage of sandwich design is not available with the same.

In the wafer lug type and wafer type, the valves are designed to permit installation between

ASME/ BS/ DIN flanges. The difference between the wafer lug and wafer type body design is that the former has provision for all the studs to pass through the body whereas the latter has provision for only locating bolts. The wafer lug design is also called single flange design.

Body/Disc:

There are different body/disc designs available in this type of butterfly valve:

In certain designs, the body is lined with a resilient material such as Nitrile rubber. Ethylene Propylene Diene Monomer (EPDM), PTFE. The metallic disc with or without coating ensures proper sealing against these liners. By selecting proper disc material, this type of valve can be used for corrosive services. The body could be of any material. There are no gaskets needed for the installation of these valves.

In certain other designs, the body will be provided with soft seat instead of a liner. This seat flexes against the sealing edge of the disc when the valve is closed. The seat is made of PTFE with certain reinforcements. This seating is designed to replace the PTFE seats when worn out.

Another design is the offset shaft and eccentric disc design which imparts camming action to the disc. In this, the stem centre line, the disc centre line and the pipe centre lines are offset.

This feature causes the disc to swing completely out of contact with the seat upon opening, eliminating wear points at top and bottom of seat. On closing, the disc moves tightly into the flexible lip for reliable seating around the entire seat.

Shaft:

As far as the shaft is concerned, there can be a single shaft or a main shaft and a stub shaft in butterfly valve.

at the bottom of the disc. Single shaft is a better design as it minimizes the deflection.

Shaft seal and bearing:

The shaft sealing can be done with ‘O’ring or stuffing box and packing. These valve design provides inherent emission control advantages over rising steam valves.

Handle:

Butterfly valve upto 12” NB is operated with lever. The lever can have positions to control the flow.

Higher diameter valves are provided with gear unit and hand wheel. When used as control valves, these can be provided with actuators also.

Limitations:

The use of this type of butterfly valve for high temperatures is limited by the material used for seats.

Only resilient seats can provide positive shut off. Metallic seating can also be provided for use at higher temperatures but will not provide positive shut off.