Introduction to Flush Bottom Valve

Flush Bottom Valve is a special purpose valve, which is used in piping, reactors and vessels to drain out abrasive, Slurry, Viscous Material or Semi Solid Media.

This type of valve is available in the size from 15 MM to 150 MM with different material of construction like Cast Iron, Cast Steel, SS 304 / 316 or any special alloy to suit user requirements. The valves seating are Teflon / Neoprene / Viton depending on the process.

This type of valve is attached to the vessels on pad type nozzle. The disks in closed position match with the bottom of the vessel or piping leaving no room for hold up or stagnation.

There are two types of flush bottom valves.

- Valves with disk opening into the tanks.

- Valves with disk into the valve

In the first case the stem pushes the disk into the tank to drain the liquid. This type cannot be used when there are any internals which restrict the movement of the disk. The drain of the material could be effected completely. In the second case, the disk gets pulled down into the valve effecting the discharge of material.

There are normally two type of disk design available, the plug type and the ram type.

Flush bottom plug type valve |

Ram type |

Normally, the inlet size of a standard flush bottom valve is one size higher than that of the outlet size. There are special constructions possible with both sizes same. The outlet port is at an angle to the inlet port. Normally 45 or 60 degrees deviation is provided. The end connections are normally flanged. However, smaller size sample/drain valves have been developed with welding end at inlet to withstand higher pressures. The maximum rating available at present for flanged valve is ANSI 300 lbs.

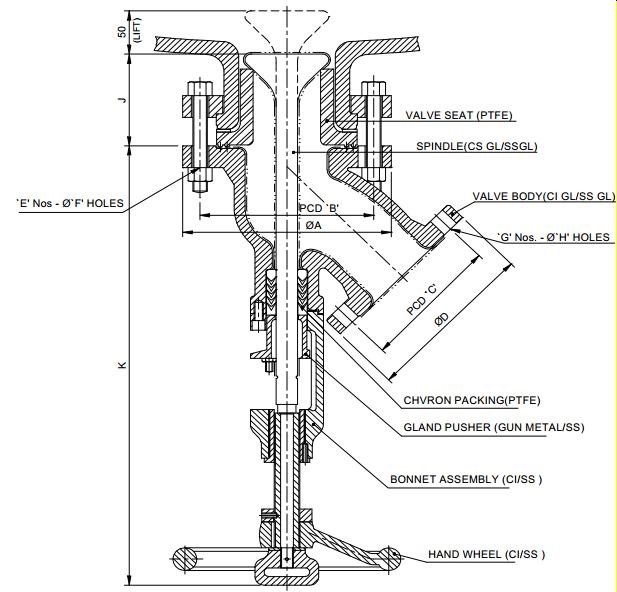

Parts of Flush Bottom valve:

Parts of Flush Bottom valve

The parts of the flush bottom valve are identical to that of a globe valve and the closing and opening actions are also similar. The shut off is achieved by disk closing against the body seat.

Jacketed flush bottom valves are also possible depending on the service. The disk and seat also could be machined to such accuracy to serve the vacuum duty as well.