Mass Flowmeter

THERMAL MASS FLOWMETER

CORIOLIS MASS FLOWMETER

THERMAL MASS FLOWMETER

- Operates by monitoring the cooling effect of a gas stream as it passes over a heated transducer.

- Gas flow passes over two PT100 RTD transducers.

- The temperature transducer monitors the actual gas process temperature, whilst the self-heated transducer is maintained at a constant differential temperature by varying the current through it.

- The greater the mass flow passing over the heated transducer, the greater current required to keep a constant differential temperature.

- The measured heater current is therefore a measure of the gas mass flowrate.

Thermal Mass Flowmeter

Features of Thermal Mass Flowmeter

- Design Pressure: 1200 PSIG

- Design Temperature: 176 Deg. C

- Sizes: 15 mm to 1000 mm

- Fluids : Clean gases

- Flow range: 0 – 2500 SCFM

- MOC: mostly in stainless steel/ glass, teflon, monel

- Accuracy is +1% to + 2% of flowrate

- Range ability is 10 : 1 to 100:1

- Upstream length/ Downstream straight length is 5/ 3

Advantages of Thermal Mass Flowmeter

- No temperature or pressure compensation required

- Linear output (as temperature differential is proportional to mass flow)

- Can be used on corrosive process streams if proper materials are specified

- DC voltage or 4 to 20 mA dc outputs available

Disadvantages of Thermal Mass Flowmeter

- Practical for gas flows only

- Subject to blockage by foreign particles or precipitated deposits due to small openings in flowmeter

- Power requirements excessive in larger pipe sizes

- Has to be taken out of process line for servicing

- Accurate field calibration is difficult

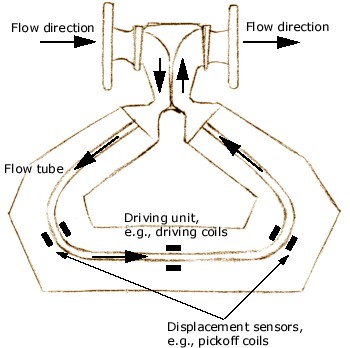

CORIOLIS MASS FLOWMETER

- When a moving mass is subjected to an oscillation perpendicular to its direction of movement, Coriolis forces occur depending on the mass flow.

- When the tube is moving upward during the first half of a cycle, the fluid flowing into the meter resists being forced up by pushing down on the tube.

- On the opposite side, the liquid flowing out of the meter resists having its vertical motion decreased by pushing up on the tube. This action causes the tube to twist.

- This twisting movement is sensed by a pick up and is directly related to mass flow rate

Coriolis Mass Flowmeter

Features of Coriolis Mass Flowmeter

- Design Pressure: 345 bar

- Design Temperature: 200 to 426 Deg. C

- Sizes: 1.5 mm to 150 mm

- Fluids/ Applications : Liquids (clean/ dirty/viscous/ slurries) clean /liquified gases

- Flow range: 0 – 25000 lb/m

- MOC: mostly in stainless steel, hastelloy/titanium

- Accuracy is + 0.15% to + 0.5% of flowrate

- Range ability is 20 : 1

- Bidirectional flow measurement

Advantages of Coriolis Flowmeter

- Capable of measuring difficult handling fluids

- Independent of density changes, flow profile and flow turbulence. Hence straight lengths are not required.

- No routine maintenance required since no moving parts

- High accuracy

Disadvantages of Coriolis Mass Flowmeter

- Not available for large pipes (upto 150 mm only)

- High flow velocities required for detection resulting in high pressure drop

- Expensive compared to other flowmeters

- Difficulty in measuring low pressure gases.