Stud Bolt Length Calculation:

Calculating the stud bolt length is one of the activities needed to be performed by the requisition engineer. The major factors which contribute towards the calculation of the stud bolt length are: Flange rating, dimensional standard, type & thickness of gasket, flange facing, sandwich type components (eg.spectacle blind, wafer type valves etc.)

As per Nonmandatory Appendices C of ASME B16.5 (2009), the Method for Calculating Stud Bolt Lengths is detailed below:

Method For Calculating Stud Bolt Length:

The following equations were used in establishing dimension L as listed in various dimensional tables:

LCSB =A + n

LCMB=B + n

For lapped joints, calculate stud bolt and machine bolt length as follows:

(a) For ring joint groove facing

LCSB=A + (pipe thickness for each lap) + n

LCMB=B + (pipe thickness for each lap) + n

(b) For other than ring joint facing

LCSB=A − F + (Table C-1 thicknesses) + n

LCMB=B − F + (Table C-1 thicknesses) + n

Where

A = 2(tf+ t + d) + G + F − a (i.e., stud bolt length exclusive of negative length tolerance, n)

a = zero, except where the small female face is on the end of pipe, a p 5 mm (0.19 in.)

B = 2(tf+ t) + d + G + F + p − a (i.e., machine bolt length exclusive of negative tolerance, n)

d = heavy nut thickness (equals nominal bolt diameter,see ASME B18.2.2)

F = total height of facings or depth of ring joint groove for both flanges (see Table C-2)

G = 3.0-mm (0.12 in.) gasket thickness for raised face, male and female, tongue and groove flanges; also approximate distance between ring joint flanges listed in Table 5 (Table II-5 of Mandatory Appendix II)

LCMB= calculated machine bolt length as measured from underside of head to end of point

LCSB= calculated stud bolt length (effective thread length, excluding end points)

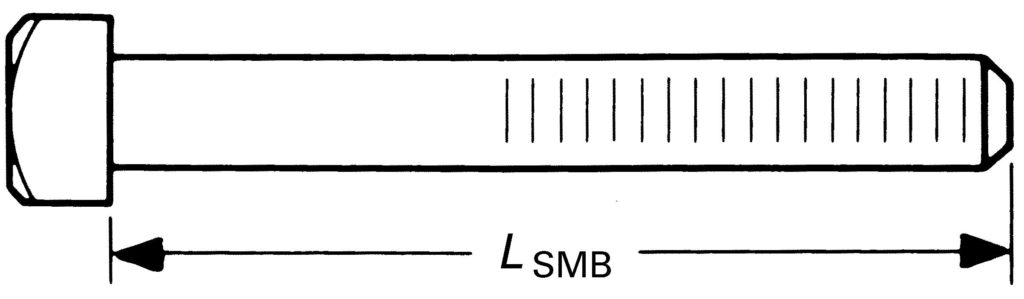

LSMB= specified machine bolt length (from under side of head to end, including end point), which isLCMB rounded off to the nearest 5-mm (0.25 in.)increment (see Fig. C-2)

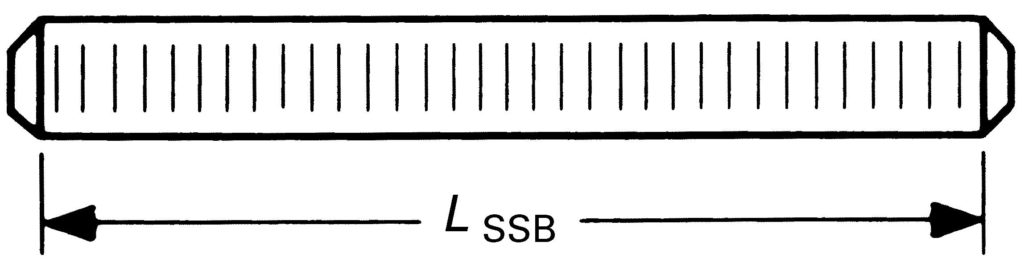

LSSB= specified stud bolt length (effective thread length, excluding end points), which is LCSBrounded off to the nearest 5-mm (0.25 in.) increment(see Fig. C-1)

n = negative tolerance on bolt length (see Table C-3)

p = allowance for height of point of machine bolt

(1.5 times thread pitch)

t = plus tolerance for flange thickness (see para. 7.4, ASME B16.5)

tf= minimum flange thickness (see applicable dimensional tables)

Fig. C-1 Specified Stud Bolt Length

Fig: C-2 Specified Machine Bolt Length

Table C-1 Thickness for Lapped

| Lap Combination | Classes 150 Through 2500 Flanges |

| For lapped to 2-mm (0.06 in.) male face on flange | One lap and 2 mm (0.06 in.) |

| For lapped to lapped | Both laps |

| For lapped to 7-mm (0.25 in.) male face on flange | One lap and 7 mm (0.25 in.) |

| For lapped to female face on flange | One lap not less than 7 mm (0.25 in.) |

| For male in lap to female in lap | 2 _ pipe wall with lap for male not less than 7 mm (0.25 in.) |

Table C-2 F Values

|

Total Height of Facings or Depth of Ring Joint Groove for Both Flanges, F, mm (in.) |

||||

|

Type of Flange Facing [Note (1)] |

||||

| Class | 2 mm Raised0.06 in. | 7 mm Raised0.25 in. | Male and Female Or Tongue and Groove | Ring Joint |

| 150 and 300 | 4 mm (0.12) | 14 mm (0.50) | 7 mm (0.25) | 2 x groove depth |

| 400 to 2500 | 4 mm (0.12) | 14 mm (0.50) | 7 mm (0.25) | 2 x groove depth |

NOTE:

(1) See Fig. 8 (Fig. II-8 of Mandatory Appendix II) and Tables 4 and 5 (Tables II-4 and II-5 of Mandatory Appendix II).

Table C-3 n Values

| Dimensions | Negative Tolerance on Bolt Lengths, n, mm (in.) | Length, mm (in.) |

| Stud Bolt AOr

[A + (pipe thickness for each lap)]

or [A − F + (Table C-1 thickness)] |

1.5 (0.06)3.0 (0.12)7.0 (0.25) | ≤305 (≤12)>305 (>12), ≤460 (≤18)>460 (>18) |

| Machine BoltB

Or [B + (pipe thickness for each lap)]Or [B − F + (Table C-1 thickness)] |

For n values, use negative length tolerances per ASME B18.2.1 |

Thank you