In the previous post I explained different types of steam trap, in this post I will discuss about different steam trap arrangements on the steam headers running in the chemical plant.

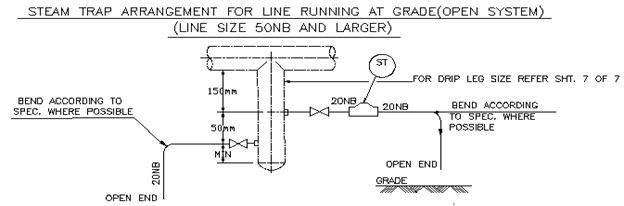

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| HALF COUPLING | 2 | 20 |

| PIPE | 1 m | 20 |

| VALVE (GATE / GLOBE) | 2 | 20 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 20 |

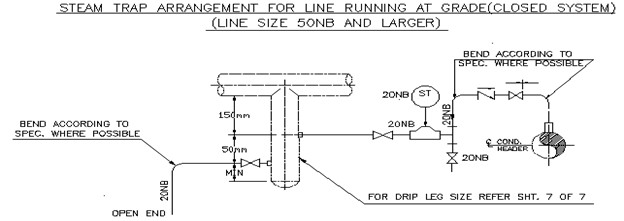

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| HALF COUPLING | 2 | 20 |

| PIPE | 15 m | 20 |

| VALVE (GATE / GLOBE) | 4 | 20 |

| CHECK VALVE | 1 | 20 |

| EQUAL TEE | 1 | 20 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 20 |

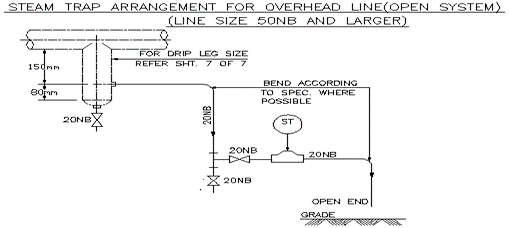

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| HALF COUPLING | 2 | 20 |

| PIPE | 12 m | 20 |

| VALVE (GATE / GLOBE) | 3 | 20 |

| EQUAL TEE | 1 | 20 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 20 |

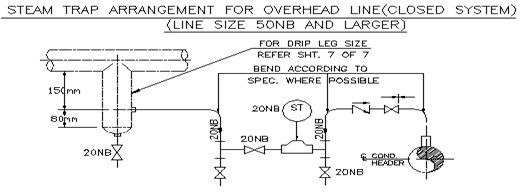

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| HALF COUPLING | 2 | 20 |

| PIPE | 18 m | 20 |

| VALVE (GATE / GLOBE) | 5 | 20 |

| CHECK VALVE | 1 | 20 |

| EQUAL TEE | 2 | 20 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 20 |

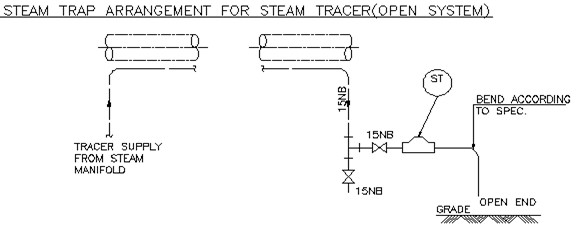

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| EQUAL TEE | 1 | 15 |

| VALVE (GATE / GLOBE) | 2 | 15 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 15 |

| PIPE | 2 m | 15 |

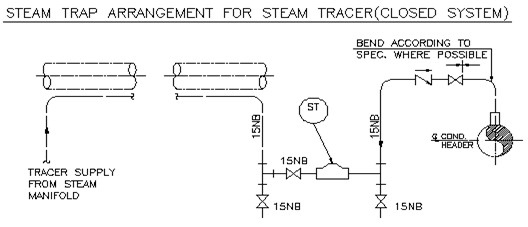

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| EQUAL TEE | 2 | 15 |

| VALVE (GATE / GLOBE) | 4 | 15 |

| CHECK VALVE | 1 | 15 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 15 |

| PIPE | 10 m | 15 |

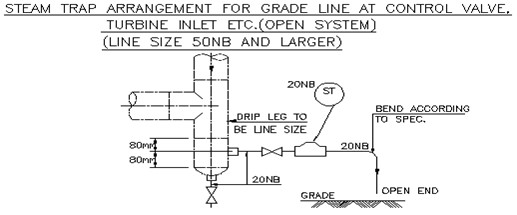

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| HALF COUPLING | 2 | 20 |

| PIPE | 0.6 m | 20 |

| VALVE (GATE / GLOBE) | 2 | 20 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 20 |

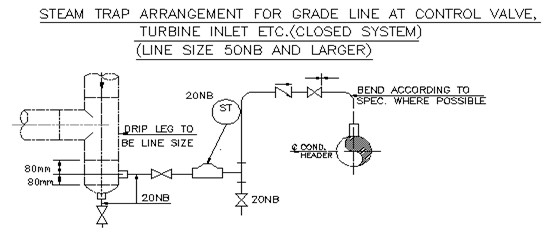

| MATERIAL LIST | ||

| ITEM | QTY | SIZE (NB) |

| HALF COUPLING | 2 | 20 |

| PIPE | 15 m | 20 |

| VALVE (GATE / GLOBE) | 4 | 20 |

| CHECK VALVE | 1 | 20 |

| EQUAL TEE | 1 | 20 |

| STEAM TRAP WITH INTEGRAL STRAINER | 1 | 20 |

MAXIMUM SPACING OF STEAM TRAPS & DRIP LEGS

-

THIS GUIDE IS AN APPROXIMATION FOR MAXIMUM SPACING OF STEAM TRAPS WHEN USED FOR CONDENSATE DRAWING OF STEAM SUPPLY HEADERS

METRES

(FEET) - IT IS BASED ON A CONDENSATE FORMATION RATE OF 70 TO 80 KG/HR (150 TO 180 LB/HR) UNDER NORMAL RUNNING CONDITIONS FOR INSULATED STEEL PIPE AT 150C (600F) AMBIENT TEMPERATURE.

- DURING THE WARMING UP PERIOD IT IS POSSIBLE THAT THE CONDENSATE FORMATION RATE WILL ON AVERAGE EXCEED THE NORMAL FORMATION RATE BY A FACTOR OF 10.

| SATURATED STEAM PRESSURE

kg/cm2 (PSIG) |

STEAM SUPPLY HEADER SIZE | MM | ||||

| (INCH) | ||||||

| 80 & UNDER (3″ & UNDER) |

100 & 150 (4″ & 6″) |

200 & 250 (8″ & 10″) |

300 & 400 (12″ & 16″) |

450 & 500 (18″ & 20″) |

600 (24″) |

|

| 9 (125) |

150 (500) |

150 (500) |

120 (400) |

105 (350) |

90 (300) |

75 (250) |

| 18 (250) |

150 (500) |

135 (450) |

90 (300) |

90 (300) |

75 (250) |

60 (200) |

| 32 (450) |

120 (400) |

105 (350) |

90 (300) |

75 (250) |

60 (200) |

45 (150) |

| 42 (600) |

120 (400) |

105 (350) |

75 (250) |

75 (250) |

60 (200) |

45 (150) |

| 63 (900) |

120 (400) |

90 (300) |

75 (250) |

75 (250) |

60 (200) |

45 (150) |

| HEADER NOM. DIA mm (inch) |

DRIP LEG DIMENSIONS |

| mm (inch) |

|

| 20

(3/4″) |

20

(3/4″) |

| 25

(1″) |

25

(1″) |

| 40

(1 1/2″) |

40

(1 1/2″) |

| 50

(2″) |

50

(2″) |

| 80

(3″) |

80

(3″) |

| 100

(4″) |

100

(4″) |

| 150

(6″) |

150

(6″) |

| 200

(8″) |

150

(6″) |

| 250

(10″) |

150

(6″) |

| 300

(12″) |

150

(6″) |

| 350

(14″) |

200

(8″) |

| 400

(16″) |

200

(8″) |

| 450

(18″) |

200

(8″) |

| 500

(20″) |

200

(8″) |

| 600

(24″) |

200

(8″) |

| 750

(30″) |

250

(10″) |

| 900

(36″) |

250

(10″) |

| 1050

(42″) |

250

(10″) |

| 1150

(46″) |

250

(10″) |