We all have heard about optical fibre and its wide applications in various industries. But many of us know very little about its features and reason for its usage in different applications. This post gives some brief knowledge & features of optical fibre used in oil and gas industry.

1. Optical Communication

–became a part of daily life due to

- Tremendous increase in communication requirement

- Tremendous Requirement of Data Transmission

- Internet communication

- Cable TV

- Information security

- Signaling and Control requirement

- Intelligent Security systems

2. Why Optical Communication?

–a revolution in communication by virtue of

- Secured communication due to use of light as signal in glass

- Less signal loss over transmission length

- Low power requirement

- Digital Transmission, hence clarity

- Non-flammable transmission media

- Lightweight transmission media

- Flexible transmission media

- Immune to EMI, RFI

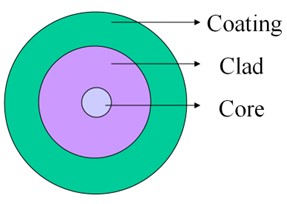

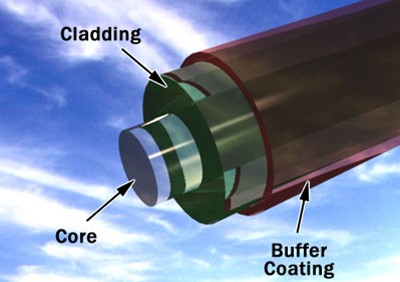

3. Optical Fibre: Basic Construction

- Basic construction :

- Core

- Cladding

- Coating

- Transmission media : Glass

- Signal : Light

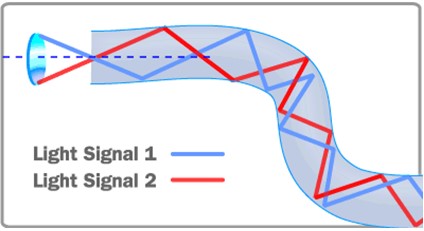

- Working principles : Total internal reflection

- Single mode Fibre: For Long Haul Communication, High Bandwidth, Low attenuation

- G 652 Fibre

- G653 Fibre

- G655 Fibre

- Multi modeFibre: Short haul communication, like LAN, WAN

- Multi mode 50 / 125 microns

- Multimode 62.5/125 microns

- Aggressive exploration in deep water areas

- Substantial increase in real time data generation and transmission to other location

- Requirement for deployment of more sophisticated process control systems in offshore

- Increase in automation to reduce manning cost at offshore rigs

- Better communication between offshore and onshore locations

- Improve life of personal working on offshore rigs

- Offshore

- Onshore

- Refinery

- Transportation

- Inter-office communication / Data Transfer

- Project sites control

- Communication link between adjacent platforms

- Communication link between Process Well to Process Platforms

- Communication with Un-manned platforms

- Communication between Offshore & On-shore installation

- Process control

- High Noise Sub-sea machinery controls due to Noise Immune communication

- Reduced size of umbilical

- Data transfer and Communication between various land installations / offices

- Secure communication systems with high speed transfer rates

- Monitoring & control of project sites

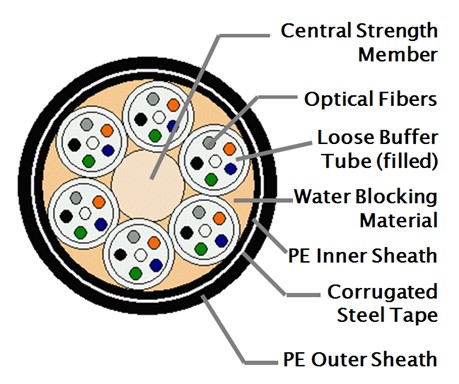

- Mechanical Strength

- Easy and quick installation

- Longer lengths

- Light weight & flexibility

- Protection against chemicals , environment

- Corrugated Steel Tape Protects Against Rodents and Rough Terrain

- Single Jacket and Multi-jacket Designs Available

- Standard Fiber Counts up to 288 (Custom Available)

- Very high Tensile strength depending upon installation conditions (varies from 20kN to higher)

- Heavy weight in order to get into the sea bed

- Strong mechanical protection against external damages

- Very high weight to diameter ratio

- Steel wire armouring to protection against external pressure (single 0r multiple layers

- Single Jacket and Multi-jacket Designs Available

- Standard Fiber Counts up to 96 (Custom Available)

- Less Installation cost and time due to smaller size & light weight

- Very less cost of cable w.r.t availability of no. of channels

- There is no atmospheric interference on OFC communication

- Less maintenance cost due to quick fault location and repair

- Less joints due to longer length hence less cost of link

- Higher bandwidth

- Highly reliable

- Immune to atmospheric conditions

- No recurring cost

- Low latency (less than 10ms)

- Highly secured

- No recurring cost compared to WPC charges for Microwave communication

- Less maintenance compared to Microwave , where we have to maintain the antenna tower

- There is no atmospheric interference on OFC communication

- Communication

- Data transfer

- Process control & monitoring

- Un-interrupted & secure information flow across various installation

- Reduction in manning cost at offshore rigs

- Additional business opportunity for bandwidth leasing

- Safety & Security of installations

Optical fibre coating

Optical Fibre: Basic Construction

Optical Fibre Working principles

4. Optical Fibre Types

5. Optical Fibre in Oil & Gas sector

Demand of Oil & Gas Industry for broadband communication has been high due to following factors;

6. Application area of Optical Fibre in Oil & Gas sector

7. Application of Optical Fibre in Oil & Gas sector

Offshore

On-Shore

8. Cable designs for Land Application

Basic Requirements of optical fibre:

Features / Advantages of optical fibre

Typical Construction of optical fibre

Optical Fibre Typical Construction

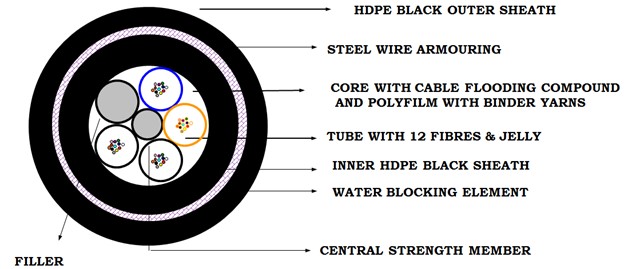

9. Cable design for Submarine application

Basic Requirements of optical fibre:

Features / Advantages of optical fibre

Typical Construction of optical fibre

Cable design for Submarine application

10. Optical communication Vs Conventional system

Benefits of optical communication over conventional system

| Copper | Optical Fibre |

| High Losses | Low Losses |

| Costlier | Less Expensive |

| Unsecured | Secured & Reliable |

| Immune to EMI, RFI | Free from EMI, RFI |

| Limited BW | Unlimited BW |

| Shorter Life | Longer Life |

Great article.