Inverted Bucket Steam Trap:

As mentioned in my previous post the inverted bucket steam trap is a mechanical trap classified as a density operated steam trap which operates on the difference in density between steam and water.

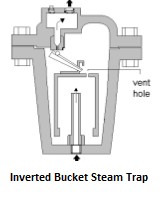

The accompanying sketch below shows the constructional details of an Inverted Bucket Trap.

As the name implies the working portion of the Trap consists of an Inverted Bucket attached through a lever mechanism to a valve. A vent hole provided in the flat bottom of the Inverted Bucket is essential for initial venting of the cold air during start up operation. Similarly a water seal must be maintained at the bottom rim of the bucket to prevent blowing of live steam.

Figure-1 (Exhibit 34.4) Inverted bucket steam trap |

Inverted bucket steam trap |

Figure-1 (Exhibit 34.4)

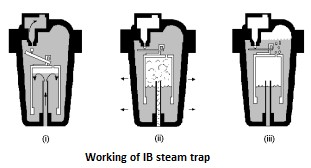

The sequence of working of the trap is shown in the sketch (refer Figure-1, Exhibit 34.5) below

Figure-1 (Exhibit 34.5) Working of IB stream trap

In position 1 the trap body is full of Condensate. The bucket therefore tries to settle under its own weight, pulling down the valve off its seat. Consequentially the condensate is pushed out through the open discharge port.

In Position 2 the mixture of Condensate and Steam enter the trap body. The Condensate settles down at the bottom while the steam occupies the upper space of the Inverted Bucket by displacing the Condensate which, continues to flow through the open discharge port.

With more and more steam displacing the Condensate from the bucket, causes the bucket to float up to close the discharge port before the steam could push the Condensate further down to blow the bottom seal and escape through the discharge port.

With lapse of time as the steam filled in the upper portion of the Inverted Bucket condenses,the bucket once again gets filled with condensate to gradually settle down under its ownweight, causing the cycle from position 1 to repeat.

The venting of cold air during the initial startup is achieved by a tiny hole provided at the top of the Inverted Bucket.

On filling of the bucket with cold air (which does not condense unlike steam) the same is allowed to escape through the above hole. The vent hole size cannot be made disproportionately large to prevent (rather reduce) the loss of live steam by bubbling through the above hole during normal operation.

A practical approach in sizing the vent hole is therefore a compromise between its air venting capacity vis-à-vis the loss of live steam during normal operation of the Trap.

Salient Features of Inverted Bucket Steam Trap:

- Limited capacity as far as venting of cold air during start up is concerned.

- Must maintain water seal. Loss of water seal will defeat the functioning of the Trap.

- All Inverted Bucket Traps incur some amount of steam loss (bubbling through the venthole).

- The condensate discharge is not continuous. Hence reduced heat transfer efficiency.

- The above traps are suitable for operating at fairly high pressures.

- The above traps have a fairly high resistance to water hammer since the condensate /steam is lead to a reasonably large volume of the bucket.

- The above traps must be protected from freezing under subzero ambient conditions.