Introduction to Multi-port Valve

Valves which perform duties other than the two way isolation, control and check are classified under the category of special purpose valves, few of such valves are

-

Multi-port valves.

-

Flush bottom valves

-

Float valves

-

Foot valves

Multi-port Valves

Multiport valve is categorized as a special purpose valve. The multi-port valve on certain services reduces the time for operating and the overall cost.

The two type of multiport valve available are: three-port valve and four-port valve.

1. Three-port multi-port valve:

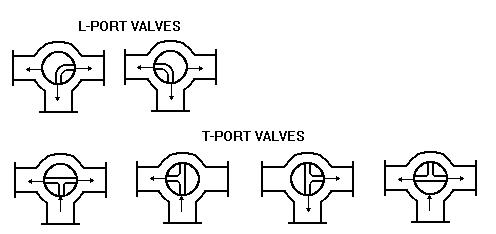

As the name suggest there are three connections for inlet/outlet for the valve. There are two types of three-port designs are available viz. The ‘T’ port and the ‘L’ port. The possible flow patterns of these are as below:

Multiport valve |

|

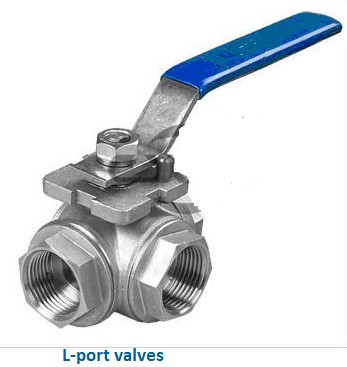

L port valve |

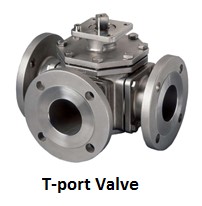

T port valve |

A most economical layout could be selected from the study of above flow patterns. The typical applications of the three-way valves are-

-

Alternate connection of the two supply lines to a common delivery.

-

diversion of flow to either of two directions

-

isolation of one of a pair of safety valves for maintenance purpose

-

division of flow with isolation facility

2. Four-port multi-port valve:

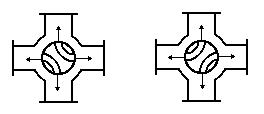

As the name suggest there are four connections for inlet/outlet for the valve.The flow patterns of a four-way valve are as shown below-

The typical applications of four way valves are:

-

Reversal of pump suction and delivery

-

By pass of strainer or meter

-

Reversal of flow through filter, heat exchanger or dryer.

Four port multi-port valve |

Four port valve |

The type of valves used for this design is the ball or the plug valves. However, globe pattern valves also can be designed with suitable disc positions to achieve the three port design. The advantages of multi-port design valves are-

-

Reduction in number of valves used

-

Quick and easy operation

-

Simplification of piping layout and thus economy in fittings

-

Less risk of product mixing by incorrect valve operation

The stops can be arranged to arrest the unrequired flow patterns and at the same time make it impossible for undesired positions to be obtained.Two of the multi-port valves can also be inter coupled to permit fast multiple operation in the simplest possible way and with minimum manpower.It is essential for the designer to specify the exact requirement of flow patterns based on the piping arrangement to the manufacturer. Lack of proper coordination will result in a totally different output than what is required.