Introduction to flange joint

Classification of flanges based on pipe attachment

1.1) Slip-on flanges

1.2) Socket-Weld flanges

1.3) Screwed/Threaded flanges

1.4) Lap-joint flanges

1.5) Welding neck flanges

1.6) Blind flanges

1.7) Reducing flanges

Introduction to flange joint

Flange joint is one of the methods of pipe joints. Pipe flanges are classified in different ways based on pipe attachment, Pressure-Temperature (PT) rating, facing, face finish. Below are the flanges based on the pipe attachments.

Classification of flanges based on pipe attachment

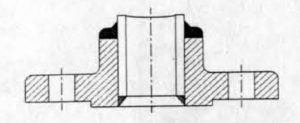

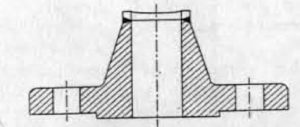

1.1) Slip-on Flanges:

These flanges are welded on inside as well as outside to the pipe. They are generally forged type with Hub. They can also be fabricated from plates but without Hub.

Pipe flanges slip-on raised face

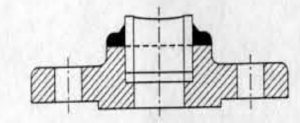

1.2) Socket-Weld Flanges:

These Flanges are welded only on outside of the Pipe. They are usually used in small bore piping where the piping specification is socket weld. They are not used in severe services due to stagnation of fluid at the socket. Socket welded flanges shall be specified with connection pipe thickness to ensure proper bore dimensions.

Pipe Flanges Socket welded raised face flange

1.3) Screwed/Threaded Flanges:

These Flanged are screwed onto outside diameter of the Pipe. They are used at locations where welding is not allowed. They are used in temperature range of 250o Deg to -450 Deg. The threads can be NPT (Nominal Pipe Threads) or BSPT (British Standard Pipe Threads) as required in the Piping specification.

Pipe flanges threaded raised face

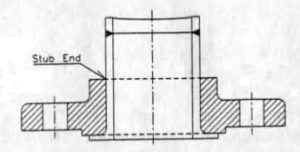

1.4) Lap-joint Flanges:

These are loose flanges used along with stub end which is butt welded to the pipe. They are used where the pipe is of higher grade or exotic material. The loose flange in many cases is of Carbon steel material. The inside diameter of the flanges are machined to fit onto the radius of stub end.

Pipe flanges lap joint stub end

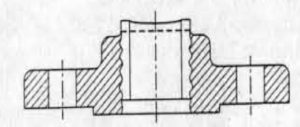

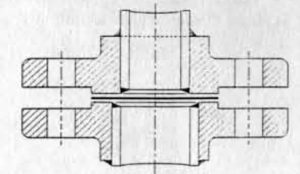

1.5) Welding neck Flanges:

These Flanges are butt welded to the pipe. As Radiography is required for all welds in critical services, these flanges are majorly used in such locations. The thickness of the flanges needs to be specified for procurement which is generally same as the pipe thickness of the same size.

Pipe flanges welding neck

1.6) Blind Flanges:

These are used to close the end of the pipe and are bolted on to the other flange. In few locations, blind flanges are procured with tapped holes for instruments or drain connection.

1.7) Reducing Flanges:

These flanges are used to connect the pipes of different diameter without the use of a reducer. The dimensions and thickness of the reducing flange should be of the larger diameter pipe but the inside diameter is to suit the smaller diameter pipe.

Pipe flanges reduced slip on

Great stuff