Piston valve resembles in construction more towards a globe valve and is mainly used for shut off and regulation.

This valve provides positive shut off. The shut off assembly comprises of a metal piston, two resilient valve rings and a metal lantern bush. The sealing surface consists of the outer vertical surface of the piston and the corresponding inner surfaces of the sealing rings. This provides a large sealing surface compared to globe valves of conventional design.

Piston valve is of two types, balanced and unbalanced. Balanced valve is used in high pressure services and unbalanced one for low pressure services.

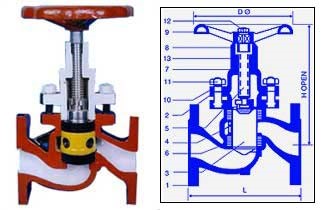

Piston valve

The main parts of the piston valve can be identified as:

- Body

- Bonnet

- Piston

- Lantern bush

- Spindle

- Sealing rings

- Yoke bush

- Indicator

- Hand wheel

- Belleville washers

- Studs nuts

- Wheel nut

- Set screw

- Spindle-Lock nut

The body is normally of cast construction. It can have screwed ends, flanged ends or butt welding ends. These valves follow the regulatory codes to DIN. There are no API or ANSI standards covering the piston valves. The end to end dimensions are to DIN 3202 which is more than a gate or globe valve of the same size to API/ASME/ BS standards. Of late, the Piston Valves are also made to ASME B16.10 dimensions. The end connections are also available to ASME/ BS standards.

The bonnet is also of the same material as that of the body and it is of bolted construction.

The piston along with the two resilient seats provides proper sealing. The upper valve ring seal to atmosphere, the lower valve ring provides seal across the ports.

The lantern ring serves as the distance piece between the two rings.

The valve rings are the heart of piston valves.

The seal rings are made from specially developed high quality elastomer material or graphite. The materials are selected depending upon the service conditions viz. The fluid in which the valve is used and its pressure temperature conditions.

Spring washers are fitted under the bonnet nuts to ensure that the pressure of the bonnet on the valve ring is kept constant. This along with the resilient sealing rings produces a spring action which compensates for any differential expansion that can occur.

There are two types of stem designs available,the inside screw rising stem and the O.S and Y type with rising stem. The hand wheel is of rising design. In O,S & Y type, a stuffing box with a bolted gland is provided. This design is mainly used for Thermic fluid services.

The piston valves are preferred by maintenance people as it needs lesser attention. They call it as ‘Fit and Forget’ type of valve.