Sizing Of Pressure / Vacuum Relief Valves

(AS PER API 2000)

A) BASIS

The following parameters need to be considered while sizing the pressure/vacuum relief valve :

1 Normal Relief : The sum of the vapour displacement resulting from filling + thermal outbreathing from storage tank or emptying + thermal inbreathing of storage tank

2 Emergency Relief : Thermal outbreathing due to exposure of storage tank to external fire

B) Pressure / Vacuum Relief Valve Settings (As per API 2521)

Pressure/Vacuum valves on atmospheric pressure fixed roof tanks are usually set at ½ oz/in2 (22 mm WG) pressure or vacuum. Test data indicates that an increase of 1oz/in2 in the pressure set point over ½ oz/in2 reduces breathing losses by approximately 7%. However, the test data indicates that each additional increase of 1oz/in2 in pressure set point reduces the breathing losses in progressively smaller increments.

C) Pressure / Vacuum Relief Valve Settings (As per API 2513)

The pressure and vacuum setting of breather valves are directed by the structural characteristics of the tank and should be within safe operating limits. A certain amount of pressure and vacuum beyond this setting is necessary to overcome pressure drop in order to obtain required flow. Proper size and settings can be best determined by reference to API 2000.

G Venting requirements in accordance with API 2000

1 To determine volumetric air flow requirements as per API 2000

a) Outbreathing (SCFH air) due to hydrocarbon movement requirements

= 6.0 or 12.0 x barrels/hr filling + thermal requirements

as per Table 1

12.0 for flash point of oil below 100o F

6.0 for flash point of oil at 100o F and above

b) Inbreathing (SCFH air) due to

Oil movement requirements = 5.6 x barrels/hr emptying + thermal

Requirements as per Table 1.

Example :

Tank Size : 100 ft dia x 60 ft high (cap 84000 barrels)

Tank contents : Gasoline (Flash Point 50o F)

Filling rate : 6100 barrels/hr

Emptying rate : 3200 barrels/hr

Outbreathing = 12 x 6100 + 53500 = 126,700 ScFH

Inbreathing = 56 x 3200 + 53500 = 71,420 ScFH

Tank capacity = Vertical storage tank

(Barrels)

Where Df = Dia in feet, Dm = Dia in Metres

Barrels = 0.14 Df 2 x height in feet

Barrels = 4.944 Dm2 x height in metres

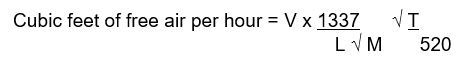

c) Emergency Venting

The volumetric air flow requirements for emergency venting as per API 2000 for any specific liquid may be determined by the following formula :

V = Cubic feet of free air from Table 2

L = Latent heat of vapourisation in BTU

M = Molecular Weight

T = Temp of Relief Valve in degree rankine

v) a) Broad specification for pressure & vacuum relief valve

– Size range 50 to 300 mm

– Pressure range 25 to 2000 mm wg

– Vacuum range 25 to 250 mm WG

– Body material – Aluminium, cast iron, cast steel, stainless steel,

– PALLETS : OPERATING RANGE

– PTFE, 35 to 100 mm

Aluminium 50 to 250 mm

stainless steel 100 to 2000 mm

with soft insert of PTFE,

Neoprene or viton

aluminium

Seats : Stainless Steel

– Allowable leakage rate

| Lit/hr | |

| 40 to 100 mm | 1.13 |

| 100 to 150 | 1.69 |

| 150 to 200 | 2.25 |

| 200 to 250 | 2.83 |

b) Broad specification for emergency vent valve

– Size range : 200 mm to 750 mm

– Pressure range : 100 mm to 250 mm WG and above

– Body material : carbon steel, stainless steel

– Seat : Stainless steel or Hastalloy “C”

– Cover : Valve pellet PTFE diaphragm + soft nitrile rubber backing ring

– Blowdown Rate : 20 to 25%

– Over Pressure : Max 50% over set pressure to minimize leakage

Can you please explain K and delta P?

Thanks in advance