Needle Valve:

The needle valve, like globe valve, is used for flow control. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates. Normally needle valve is used in smaller sizes and is provided with either screwed or socket weld ends.

Needle valve |

Needle valve |

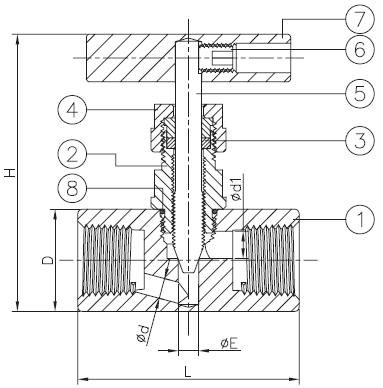

The major body parts of needle valve are-

- Body

- Bonnet

- Packing

- Nut

- Stem

- Screw

- Handle

- O-Ring

The design of the needle valve can be exactly same as that of the globe valve except for the disk. In globe valves, the disk is like a truncated pyramid whereas in the needle valves it will be full. This facility ensures finer flow control. The disk could also be integral with the stem, in which case the bottom part of the stem will be machined accordingly.

A totally different type of construction is also used for the needle valves of smaller sizes. A needle valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger, on the end of a screw, which exactly fits this seat. The body/bonnet connection will be screwed-on type instead of bolted. In place of a flanged gland with gland bolting, the packing will be positioned with a screwed union glandnut. The stem will be of inside screw arrangement. This makes the valve compact.

The body and bonnet can be of forged construction or can be fabricated from barstock. These valves are used only for limited applications. Even though the code covers this design, these are mostly made as per Manufacturers’ standard.

This valve is widely used for line shut-off, instrumentation control & for pressure regulating.

Unlike a ball valve, or valves with a rising stem, it is not easy to tell from examining the handle position whether the valve is open or closed.

these will be part of a super steam rocket—-will need 8 each x two or 16 must be servo controlled.

the needle and orives must be titaum capable of 487 dregees and 500 psi