Based on functions, valves are classified as isolation, regulation, non return valve and special type of valve.

Non Return Valve:

As the name indicates, this non return valve is used to ensure unidirectional flow of fluids. It is used to prevent the back flow in order to safeguard the critical equipments such as pumps, compressor etc and also used for positive. This non return valve is also known as Check valve. This valve is self operated valve and doesn’t require any hand wheel or gear for operation. It is available in variety of size, rating and design.

Check valve is mainly divided into below types based on check mechanism:

- Lift check valve

- Swing check valve

- Dual plate check valve

The type is selected depending upon the service, size and material of construction. Normally, small bore valves (up to 2” NB) are selected as lift check and big bore as swing check due to constructional limitations. Dual plate check valves are preferred in very large size.

Lift check valve:

This lift check non return valve operates by the lifting action of the disk/element. The different types of lift check valve available are

- Piston lift check

- Ball lift check

- Non-slam check

Piston lift check:

The piston lift non return valve has body similar to that of globe valve. The piston will be in cylindrical form, the lower end of which is shaped to form a seating disk. The cylindrical part fits into the guide making an effective dash pot. When it is in fully open position, the net area between the seating disk and the seat will be equal to the area through the seats.

The body will be provided with renewable body seat rings like in globe valves. In carbon steel valves, there can be hard faced seats deposited directly on to the body.

The lift check valves can also be provided with spring loaded piston. In this case, a spring of specified tension has to be placed, between the guide and the piston within the cylindrical portion.

The piston lift check valves can only be placed in the horizontal position.

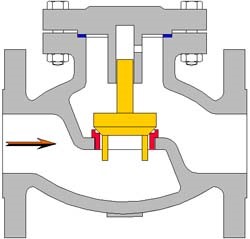

Piston lift check non return valve

Ball lift check:

In ball lift check non return valve the unidirectional flow is achieved by the movement of a ball. There are two designs possible in this pattern, the horizontal and the vertical. In vertical design, the valve should be placed in such a way that the flow is always in the upward direction.

These check valves are provided with guides to guide the ball throughout the travel. The travel should be such that in fully open position, the net area between the ball and the seat shall be at least equal to the area through the seat.

The main part of lift check valves are the following.

- Body

- Ball/piston

- Cover stud nut

- Cover seat

- Guide

- Gasket

The body shall be of forged or cast construction and with socket welded/screwed/flanged ends, integrally cast or with welded-on flanges.

The cover shall be either bolted or welded or with union nuts. The union nuts could be of hexagonal or octagonal shape. The cover material shall be same as that of the body.

The seating shall be integral or renewable. The hardness difference can also be achieved by weld deposit on seating surfaces. The renewable seat rings shall be screwed-in type either shoulder seated or bottom seated.

The body cover gasket when provided shall be suitable for the pressure-temperature rating of the valve. Normally, spiral wound metallic, or jacketed or soft iron gaskets are used.

For body/cover bolting, both carbon and alloy steel studs are used.

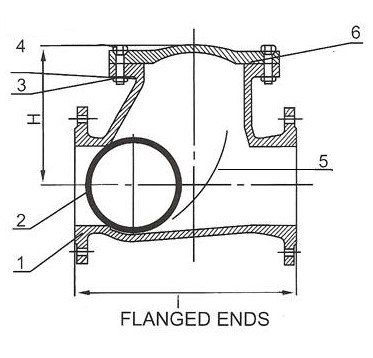

Ball lift check non return valve

Non-Slam check valve:

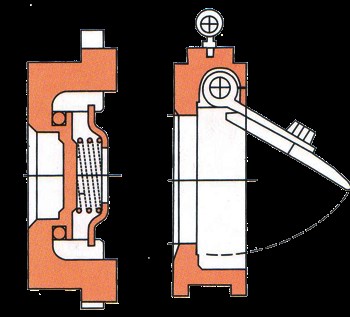

Non-Slam check valve non return valve

The non-slam check non return valve is a spring-loaded lift check valve with a modified design of the body. The valve is designed in such a way that the same can be sandwiched between the two flanges. Here the disc is held in position by a spring which is housed in a housing cap or yoke.