I. Introduction to tankfarm:

The use of tanks is common in all kinds of plants found in oil & gas industry.

- Process Plant

- Refineries

- Petrochemicals

- Specialty chemicals

- Terminals

- Administration buildings

- Material Handling Plants

Storage tank are containers used for storage of fluids for the short or long term. Cluster of tanks together in a same are termed as “Tank Farms”.

II. Types of Tanks:

Types of Tanks in Process plant depend on the product to be stored, potential for fire, and capacity to be handled.

-

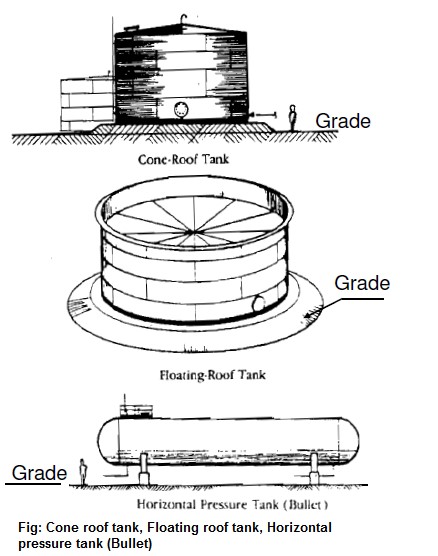

Cone roof tank:

Used for countless products including Petroleum, Chemicals, Petrochemicals, Food products & Water

-

Floating roof tank:

The roof of tank rises and lowers with the stored contents thereby reducing vapour loss & minimizing fire hazard. Commonly found in Oil refineries.

-

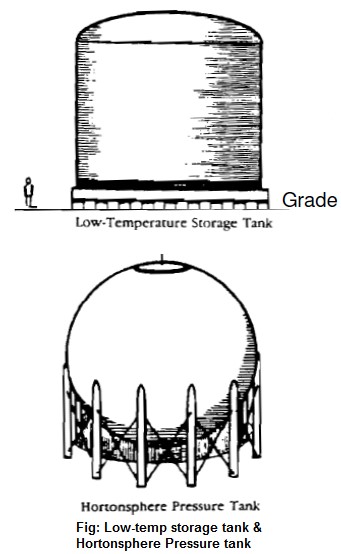

Low temperature storage tank:

Tanks stores liquefied gases at their boiling point. Products found in such tanks include Ammonia (-28 °F), Propane (-43.7 °F) and Methane (-258°F).

-

Horizontal pressure tank (Bullet):

Used to store products under high pressure.

-

Hortonsphere pressure tank:

Handles large capacity under high pressure.

-

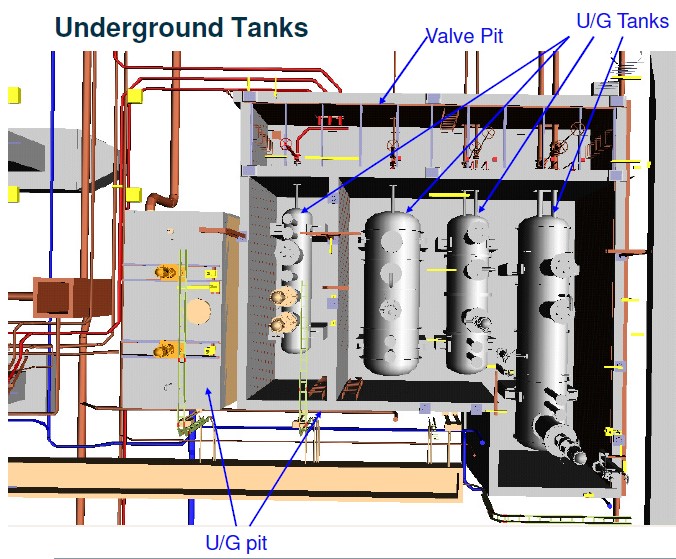

Underground Tanks:

Commonly used for drain collection of the plant at atmospheric pressure.

-

FRP Tanks:

Commonly used for corrosive fluid at atmospheric pressure.

Cone roof, floating roof, horizontal pressure tanks

Low temperature storage tank, hortonsphere pressure tank

Underground tanks

III. Design Considerations for Tankfarm Layout:

Below considerations are to taken into account while designing a Tankfarm for Process plants:

General considerations:

- Local codes and regulations

- Client specification

- Topography

- Adjacent process units

- Neighbouring commercial and residential property

- Maintenance and operation

Detail design:

- Identification of storage based on fluid stored.

- Safety considerations/Statutory requirements

- General / Plot plan arrangement

- General piping layout

- Material of Construction.

Statutory and Safety Requirements:

- Following are the key statutory requirements (India). However these are to be relooked based on geographical location:

- OISD -118 ( Plant Layout )

- OISD -116 / 117 (Fire Fighting )

- Fire Hydrant Manual & Spray Manual.

- Factory Act of State. If Any

- Petroleum Act 1934 (Act N0.30 of 1934) Along with The Petroleum Rules.

- Static and Mobile Pressure Vessel (SMPV).

- National Fire Protection Act (NFPA).

- Apart from this, local rules and regulations pertaining to State and local industrial requirement should be taken into consideration.

- Safety ensures proper protection and safe operation- Lifetime.

- Insurance Premium.

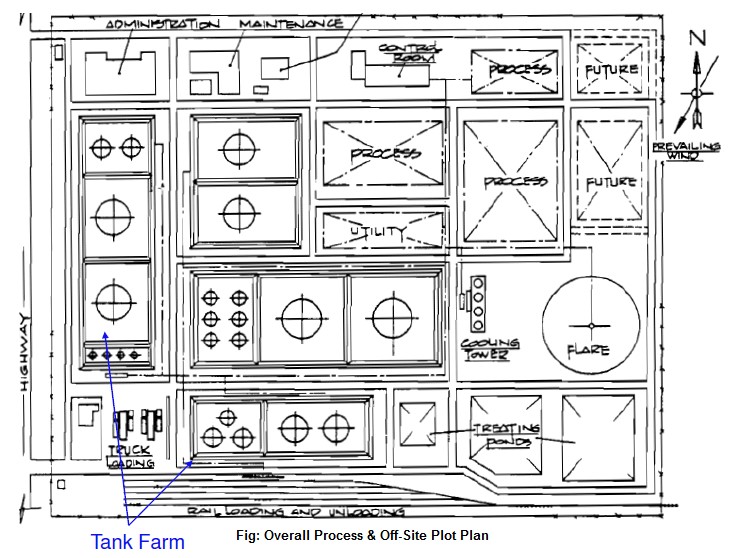

IV. Plot Plan Arrangement for Tankfarm

- Hydrocarbon processing and handling plants are inherently hazardous involving large and complex processes and substantial risk potential; hence a careful consideration shall be given while developing a plot plan.

- Plot plan is a spatial arrangement of equipment considering proper flow sequence, system grouping, safety, statutory requirements, maintenance, operation, erection and construction with logistical economy.

- General classification of petroleum products for storage.

- Class – A: Flash Point below 23 °C

- Class – B: Flash Point of 23 °C & above but below 65 °C.

- Class – C: Flash Point of 65 °C & above but below 93 °C.

- Excluded Petroleum class: Flash Point of 930 °C & above.

- LPG doesn’t fall under this classification but form separate category.

- Grouping of petroleum products for storage shall be based on product classification.

- Classification based on capacity and diameter:

- Larger installations: Aggregate capacity of Class A and Class B petroleum product is more than 5000 cu.m or diameter of Class A or Class B product tank is more than 9m.

- Smaller installations: Aggregate capacity of Class A and Class B petroleum product is less than 5000 cu.m or diameter of Class A or Class B product tank is less than 9m.

- The storage tanks shall be located at lower elevation, wherever possible.

- The storage tanks should be located downwind of process units.

- Due to risk of failure of storage tanks and primary piping systems, means must be provided to contain the spills. The containment for petroleum storage tanks is in the form of Dyked enclosures.

Tank farms in overall process off site plot plan

V. Dyke Enclosure

- Aggregate capacity in one dyke enclosure:

- Group of Fixed roof tanks: Upto 60,000 m3

- Group of Floating roof tanks: Upto 120,000 m3

- Fixed cum floating roof tanks shall be treated as fixed roof tanks.

- Group containing both Fixed roof tanks & Floating roof tanks, shall be treated as fixed roof tanks.

- Class – A and / or Class – B petroleum products :- Same dyked enclosure

- Class – C: – Preferably separate dyked enclosures.

- Tanks shall be arranged in maximum two rows. Tanks having 50,000 m3 capacities and above shall be laid in single row.

- The tank height shall not exceed one and half times the diameter of the tank or 20 m whichever is less.

- The minimum distance between a tank shell and the inside toe of the dyke wall shall not be less than half the height of the tank.

- Dyked enclosure for petroleum class shall be able to contain the complete contents of the largest tank in the dyke in case of any emergency.

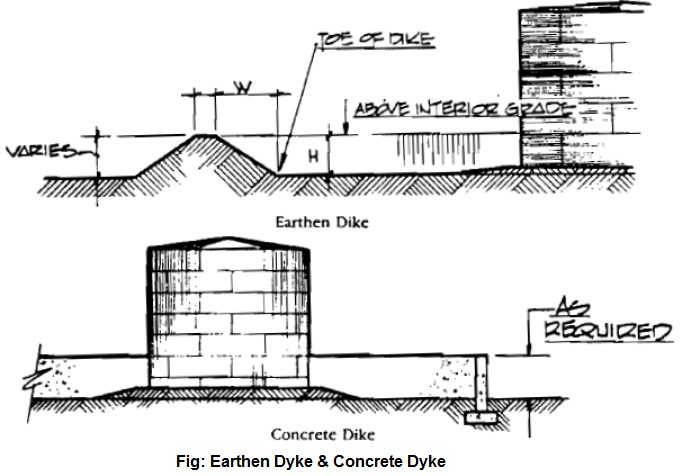

- Height of Dyke (H): 1m < H < 2m

- Width of Dyke (W): Minimum 0.6m (Earthen dyke) Not Specific (RCC dyke)

Earthen dyke and concrete dyke

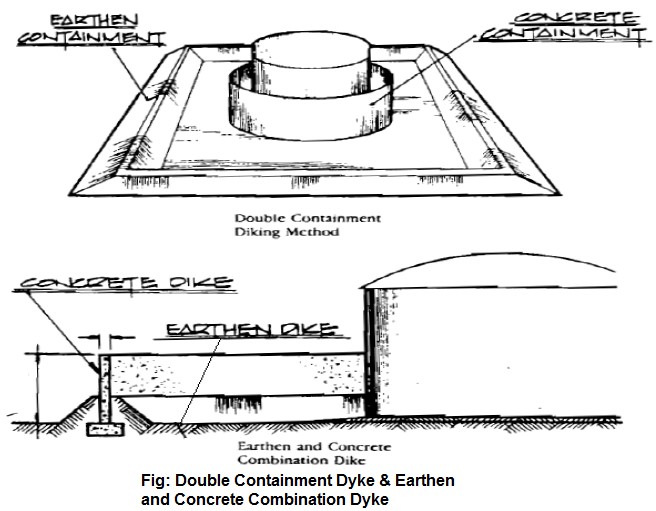

Double containment dyke and earthern and concrete combination dyke

- Separation distances between the nearest tanks located in separate dykes shall not be less than the diameter of the larger of the two tanks or 30 meters, whichever is more.

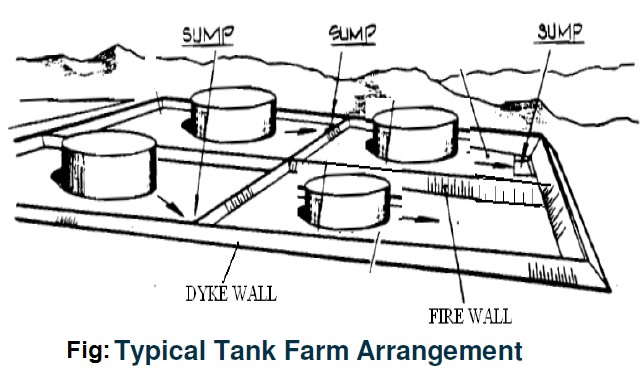

- All process units and dyked enclosures of storage tanks shall be planned in separate blocks with roads all around for access and safety.

- In a dyked enclosure where more than one tank is located, firewalls of minimum height 600mm shall be provided to prevent spills from one tank endangering any other tank in the same enclosure.

Typical tank farm arrangement

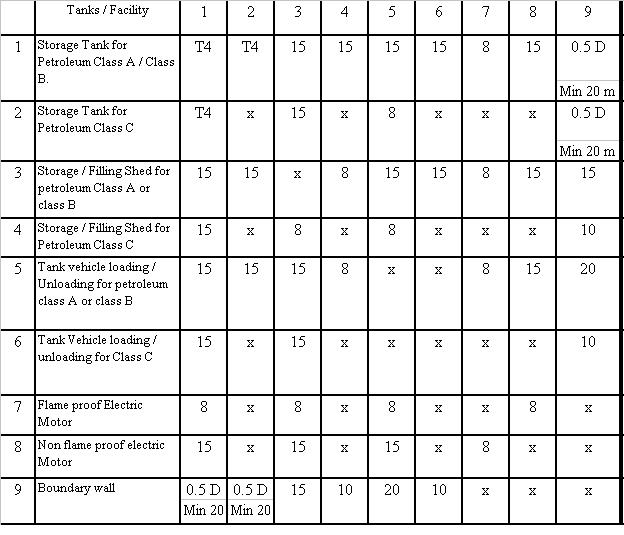

- For larger installation, minimum separation distances shall be as specified in following tables.

Table 1: Inter unit Distances for large installations (D>9m or Agg. Cap > 5000cu.m)

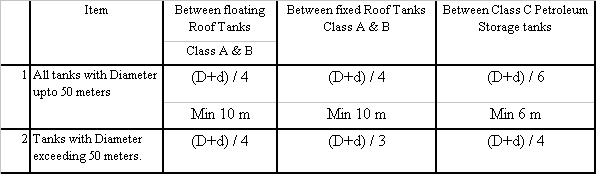

Table T4: Tank to tank distance within same Dyke

Table T4: Tank to tank distance within same Dyke

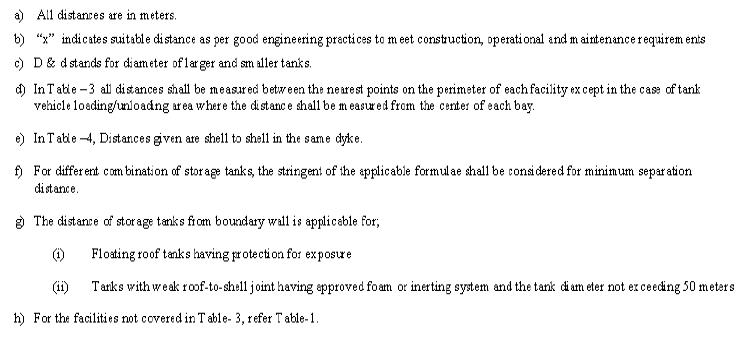

Notes for Table 1:

Table 1 notes

Table 2: Interunit Distances for smaller installations (D<9m or Agg. Cap < 5000cu.m)

Table 2: Interunit Distances for smaller installations (D<9m or Agg. Cap < 5000cu.m)

Hi,

How to decide the storage Tank design Pressure and Vacuum?

The following are given:

1. Temp.

2. Filling rate m3/min

3. Emptying rate m3/min

4. Service liquid properties, ex. Diesel

In the API std. 2.5 psig is mentioned but in the above datas, I believe that there is a formula of deciding Press and Vac for the data sheet.

At API 2000, we can decide only the venting capacity but we are not sure yet the safety relief valve Vendors the we cannot decide the Press and Vac to be used in our design.

Does, anybody an help me out?

Hi there,

Please refer to some related articles here which may help-

http://www.piping-engineering.com/pressure-vacuum-relief-valves-part-1.html

http://www.piping-engineering.com/pressure-vacuum-relief-valves-part-2.html

Cheers

AJ

The

articles are given as very useful information

NIce.

Flash point temperature for fluid should be 23 65 and 93 C instead of 230 650 and 930C

Hi Harshit,

Thank you for suggesting correction. I have updated the flash point temperatures.

Much appreciated.

Regards,

AJ

NFPA 30 and API 2030 shall be followed for tank farm fire protection system.